When it comes to maintaining the performance of your LT1 engine, the cooling system plays a critical role in ensuring optimal operation. The 192-97 LT1 cooling system lines are an integral part of this system, but understanding their importance, function, and maintenance is key for any car enthusiast or mechanic. In this article, we’ll explore everything you need to know about these cooling system lines, including their design, how they work, how to troubleshoot common issues, and how to replace or maintain them.

Introduction to the LT1 Cooling System

The LT1 engine, first introduced by General Motors in 1992, is renowned for its performance and efficiency. It is part of the Gen II small-block family and was used in vehicles like the Chevrolet Corvette, Camaro, and Firebird. The cooling system in any engine plays a pivotal role in maintaining proper engine temperature and preventing overheating. In the LT1 engine, the cooling system is designed to circulate coolant through the engine block, radiator, and other components to absorb heat and dissipate it effectively.

One of the key elements of this system is the cooling system lines, which connect various components such as the radiator, water pump, and thermostat housing. These lines are responsible for transferring coolant to and from the engine and other heat-sensitive components.

What Are the 192-97 LT1 Cooling System Lines?

The 192-97 LT1 cooling system lines refer to the specific set of coolant lines used in the LT1 engines manufactured between 1992 and 1997. These lines are crucial in the overall circulation of coolant, ensuring that heat is effectively transferred away from the engine. They connect the engine block, radiator, and water pump, forming a closed loop for the coolant.

These lines are usually made from durable materials such as rubber or metal, designed to withstand high temperatures and pressures without cracking or leaking. Over time, however, exposure to extreme heat, UV rays, and general wear and tear can cause these lines to degrade, leading to potential performance issues.

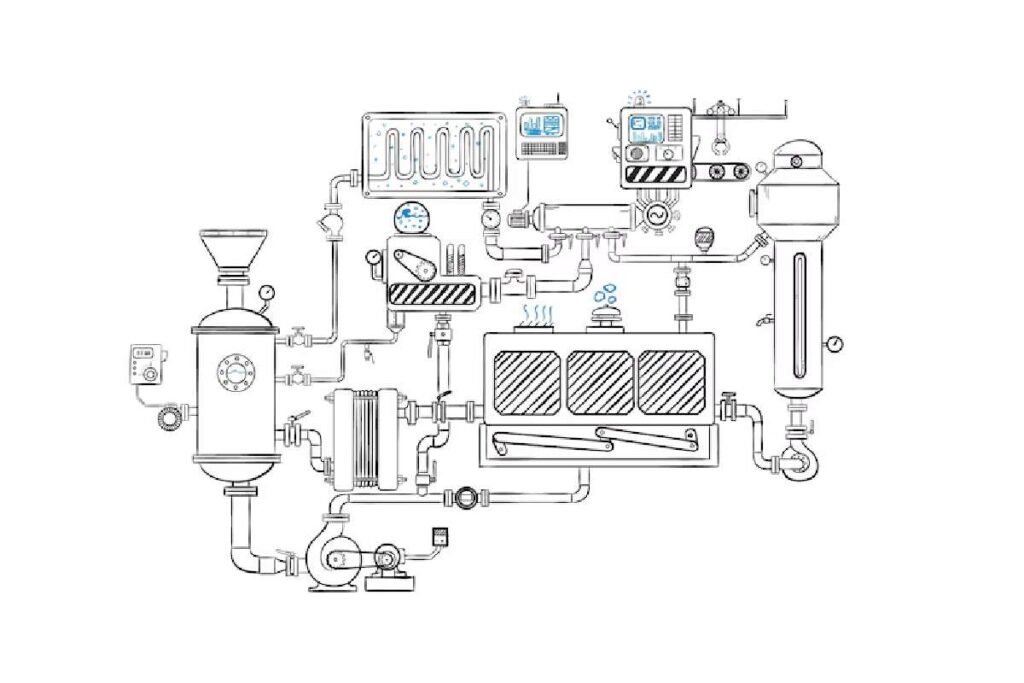

How the LT1 Cooling System Works

The cooling system in the LT1 engine is a closed-loop system that continuously circulates coolant throughout the engine to absorb and dissipate heat. The system includes various components, all of which depend on the integrity and function of the cooling lines to work effectively:

Key Components of the LT1 Cooling System:

- Radiator: The radiator is responsible for cooling the hot coolant that comes from the engine by dissipating heat through its finned core.

- Water Pump: The water pump circulates coolant throughout the engine and radiator. It is typically powered by a belt connected to the engine.

- Thermostat: The thermostat regulates the flow of coolant based on the engine’s temperature, ensuring that the engine runs at an optimal temperature.

- Coolant Lines: These lines connect the radiator, water pump, thermostat, and engine block, ensuring coolant flows freely and efficiently.

The primary purpose of the cooling system lines is to connect the various components and allow for the transfer of coolant between them. When functioning properly, the system helps prevent the engine from overheating and maintains performance. Any leaks or blockages in the cooling lines can significantly impact the system’s efficiency.

Common Problems with the 192-97 LT1 Cooling System Lines

While the LT1 engine is known for its reliability, there are a few common problems related to the 192-97 LT1 cooling system lines that enthusiasts and mechanics should be aware of:

- Leaks in the Cooling Lines

Over time, the coolant lines can degrade and crack, especially if they are exposed to extreme heat. Leaks can occur at connection points or along the length of the line itself, leading to coolant loss and engine overheating. Leaking coolant lines are a common problem that can cause the engine temperature to rise, which may lead to severe engine damage if not addressed promptly.

- Clogged or Blocked Lines

Coolant lines can become clogged due to sediment or debris within the system. Blockages can impede the flow of coolant, causing the engine to overheat. This is often the result of poor maintenance or use of low-quality coolant.

- Corrosion of Metal Cooling Lines

In the case of metal cooling system lines, corrosion is another common issue. Corrosion can weaken the integrity of the lines, making them more prone to leaks and damage. The presence of rust or other corrosion on the metal cooling lines is a red flag that replacement may be necessary.

- Deterioration of Rubber Lines

The rubber hoses used in many LT1 cooling system lines can dry out and crack over time. Rubber lines exposed to high heat and UV rays tend to degrade, leading to cracks or splits in the material.

Maintenance Tips for LT1 Cooling System Lines

Proper maintenance of the 192-97 LT1 cooling system lines is crucial for the longevity and performance of the engine. Here are some essential tips to keep your cooling system in top condition:

- Inspect Regularly

Regular inspection is essential. Look for signs of cracks, wear, and corrosion in the cooling lines. Check both the rubber hoses and metal lines, especially around connection points and bends.

- Use the Right Coolant

Always use the coolant recommended by the manufacturer. Using incorrect or subpar coolant can accelerate the deterioration of the cooling lines and other components in the system.

- Replace Damaged Lines Promptly

If you notice any leaks, cracks, or signs of corrosion, replace the affected cooling lines immediately. Waiting too long can lead to engine overheating and costly repairs.

- Flush the Cooling System

Periodically flushing the cooling system helps remove any sediment or debris that may cause clogs in the lines. A well-maintained cooling system reduces the chances of blockages and ensures smooth coolant flow.

How to Replace 192-97 LT1 Cooling System Lines

If your 192-97 LT1 cooling system lines have worn out or become damaged, replacing them is essential to maintain engine health. Here’s a step-by-step guide to help you replace the cooling system lines:

Step 1: Locate the Cooling Lines

Identify the location of the cooling system lines that need replacing. These lines typically run between the radiator, water pump, and thermostat housing.

Step 2: Drain the Coolant

Before removing any cooling lines, drain the coolant from the system. This prevents coolant from spilling out when the lines are disconnected.

Step 3: Disconnect the Old Lines

Carefully disconnect the old lines from their connection points. You may need a wrench or pliers to loosen the clamps or bolts securing the lines.

Step 4: Install the New Lines

Once the old lines are removed, install the new ones. Make sure the new lines are securely connected and tightened to prevent leaks. Use new clamps if necessary to ensure a tight seal.

Step 5: Refill the Coolant

After installing the new lines, refill the system with the recommended coolant. Bleed the cooling system to remove any air pockets, which can cause overheating if left unchecked.

Step 6: Check for Leaks

Start the engine and check for any leaks around the new lines. Ensure that all clamps and connections are secure before driving.

Comparison of 192-97 LT1 Cooling System Lines with Other LT1 Models

While the 192-97 LT1 cooling system lines share similarities with other LT1 engine models, there are distinct differences in terms of design and materials used. Here’s a comparison chart to help you understand the differences:

| Feature | 192-97 LT1 Cooling System Lines | Other LT1 Models (1997+) |

| Material | Rubber and Metal | Mostly Metal with Rubber Hoses |

| Connection Points | Multiple connection points | Fewer connection points |

| Line Thickness | Thicker rubber hoses for durability | Thinner lines for space efficiency |

| Corrosion Resistance | Moderate corrosion resistance | Better corrosion resistance in newer models |

| Ease of Replacement | Moderate | Easier due to simplified design |

As you can see, later LT1 models feature improved corrosion resistance and more compact designs, making them easier to replace and maintain. However, the 192-97 model still remains reliable if properly maintained.

Troubleshooting the LT1 Cooling System

If your LT1 engine is showing signs of overheating or poor coolant circulation, you may need to troubleshoot the cooling system. Here are some common issues and solutions:

- Coolant Leaks: Inspect the cooling lines for any visible cracks or damage. Repair or replace the affected lines as necessary.

- Overheating: Check the thermostat, water pump, and coolant levels. Replace the thermostat if it’s stuck, and make sure the water pump is functioning properly.

- Clogged Cooling System: Flush the system to remove any debris or blockages.

- Conclusion

Maintaining the 192-97 LT1 cooling system lines is essential for keeping your LT1 engine running smoothly and preventing costly repairs. Regular inspection, timely replacement, and proper maintenance of the cooling lines are critical in ensuring the longevity and performance of your engine. By following the guidelines in this article, you can ensure that your LT1 engine stays cool, performs efficiently, and continues to provide the power you expect.

By understanding the function and importance of the cooling system lines, and with the right knowledge and tools, you’ll be able to tackle any cooling system-related issues with confidence. Whether you’re a mechanic or a DIY enthusiast, keeping your LT1 cooling system in peak condition should be a priority for ensuring your engine runs at its best for years to come.